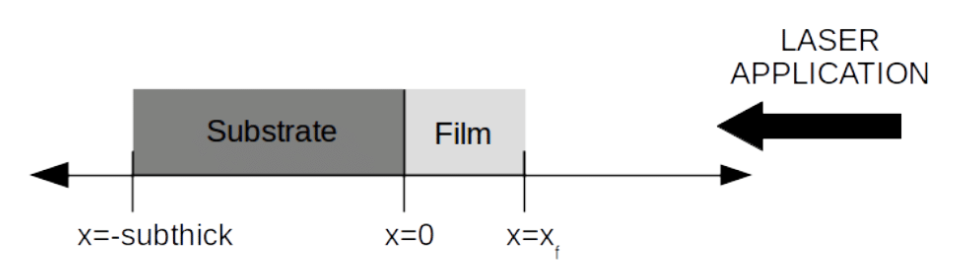

A client requested a model in MATLAB that would support his experimental work. He was dealing with laser heating of metal substrates coated with thin films. Specifically, he was interested in how pulsed laser heating drives phase change and ablation of the film.

I wrote a solver in MATLAB that used a direct finite element solver coupled with the Crank-Nicolson method for time stepping. Boundary conditions and internal heat source terms specific to laser heating were used. Film elements were coded to force element death once a latent heat criterion indicated phase change in the element. Thus, the simulation accurately predicted the rate of ablation of oil film under pulsed laser heating.

The system was subjected to long durations (seconds) of laser heating consisting of many extremely short (microseconds) pulses. In addition, the lasers simulated were very powerful, inducing high temperature gradients in the material. Therefore, proper time stepping and appropriate meshing were key to quick model convergence. The model was validated using published experimental results so that the client could confidently extend it to his experiments.